What Is a Ruggedized SSD?

Solid state drives, or SSDs, were once used exclusively for rugged operating conditions. However, the commercial market has now embraced SSDs over hard disk drives, or HDDs. As a result, not all SSDs created today are intended for use in rugged operating conditions. With this in mind, it’s essential for industrial users to ensure that the SSD they are choosing can actually stand up to the environmental demands of their application. This means choosing a ruggedized SSD for the job. Here is a look at ruggedized SSDs and the characteristics that make them unique.

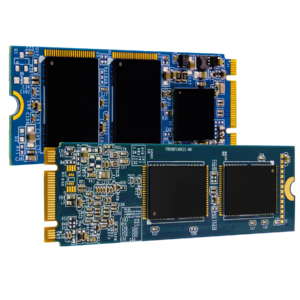

SSD Basics

SSDs were designed as an alternative to HDDs for devices in which the moving parts of the HDD caused operational issues. SSDs don’t have any moving parts. Instead of storing data on a spinning disk, SSDs rely on embedded NAND flash storage to host data. These devices store data on chips using a series of voltage changes. Because there are not any moving parts, SSDs are especially ideal in conditions in which the device may be jostled by shock and vibration, or where temperature extremes are a concern.

SSDs were embraced for industrial applications for this reason, but they have since become a go-to drive in the consumer market as well. Many computers and other devices are doing away with HDDs in favor of SSDs. For industrial customers, this means they must ensure that they truly get a ruggedized device instead of simply choosing an SSD over an HDD.

Ruggedized SSD Features

Ruggedized SSDs have specific features that allow them to operate in rugged conditions. Some of the specific characteristics of a ruggedized SSD include the following:

- Ability to operate in environments in which temperatures can be as low as -40 degrees C or as high as 85 degrees C.

- Operating shock values of 50G based on half-sine shock pulse of 11 ms

- Operating vibration values of 10Grms random 20-2000HZ

These features mean that an SSD will be operational in the extreme environments in which industrial applications are found. For industrial grade applications, choosing an SSD without these ruggedized features can lead to failures in the field that may be costly and difficult to manage.

Ruggedized SSDs are optimized for industrial conditions in a number of ways. For instance, they are designed to remove heat from sensitive components, and passive components can automatically change their value in response to extreme temperatures in order to reduce the risk of temperature-related power issues. The drives also feature mechanical, firmware, and electrical tweaks that are suited to rugged environments.

If you have questions about ruggedized SSDs, let Delkin explain how they could be used in your application. Please contact our product team to discuss your project.

Login

Login Register

Register