Taking a Closer Look at the M.2 SATA Connector

As solid state drives, or SSDs, replaced hard disk drives (HDDs) as the most popular form of embedded storage, there was an ongoing concern about the limitations of the interfaces to which the SSDs were attached. Many interfaces, such as the SATA third-generation interfaces, were specifically designed to work with HDDs and could only run with a maximum transfer speed of 6 Gb/s. The mini version of the SATA interface, mSATA, is limited to the 6 Gb/s transfer speeds, even though it is designed to work in small devices with high-speed SSDs. The M.2 SATA connector is the solution to these speed concerns. Here is what you need to know.

From NGFF to M.2

M.2 is a specification that refers to add-in cards that are mounted internally. When it was introduced to the market as a way to deal with the speed limitations of mSATA, it was called Next Generation Form Factor, or NGFF. However, it was renamed M.2 in 2013. M.2 supports SATA and PCIe interfaces, but it can only be used in one or the other. For this reason, if you are considering an M.2 SSD module for your application, it is necessary to first check your motherboard design to see if the option you are considering will be compatible.

M.2 vs. mSATA SSDs

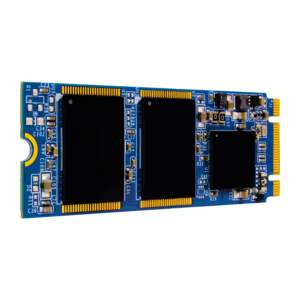

Both mSATA and M.2 are powerful SSDs that come in small packages, making them ideal for use in laptops, tablets, and other small devices. Originally, mSATA was used exclusively in these devices that had the need for a small form factor, but the speed limitations were problematic. For this reason, M.2 was created. Now, there are multiple options for small form factors that still offer high performance. M.2 generally offers higher speeds than mSATA with a smaller footprint, and it features longer modules and double-sided component population. This means that it can provide a greater amount of storage without taking up extra space. M.2 SSDs are available in three dimensions. When selecting a size, it’s important to consider thermal management. If heat dissipation is not sufficient, then there could be performance issues in the future.

If you’re considering an M.2 SATA connector, let Delkin help you weigh your options and choose the right connector for your needs. Contact our product team to discuss your design, and we will help you find the right fit for your device.

Login

Login Register

Register