Questions about the M.2 SATA Connector

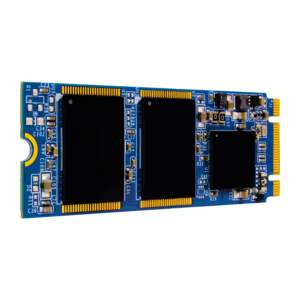

An ongoing concern that users have had about solid state drives, or SSDs, is how to use them to their peak capability when existing connectors hinder their speed. SSD technology quickly outpaced that of the interfaces to which they were connected, which meant that the drives were forced to function more slowly than they could—and often, more slowly than hard disk drives, or HDDs. The M.2 SATA connector changes that. M.2 combines the small footprint of miniSATA, or mSATA, with the capabilities needed to optimize SSD performance so that they can outpace HDDs. This interface is being used in both consumer and industrial markets and is especially important for industrial applications that need the highest possible speeds. Here are the answers to some of the questions OEMs frequently have about the M.2 SATA connector.

Does M.2 SATA replace mSATA?

M.2 SATA is one generation newer than mSATA and improves on many of the features of mSATA connectors. It is smaller than mSATA, which is particularly helpful since there is now a continuous push for smaller devices. It also provides faster performance and greater capacity than mSATA.

mSATA is limited to 6Gb/s link speeds and 1TB of capacity. These are the highest levels for SATA 3.0. M.2 SATA, on the other hand, works with SATA 3.2 and can work with PCIe interfaces, giving users the greatest potential for speed and capacity.

Can M.2 SATA be connected via both SATA and PCIe?

While M.2 SATA supports both of these interfaces, a particular connector will only work with one or the other. Before choosing an M.2 SATA SSD, you need to verify that the module fits and will work with the appropriate socket on the motherboard. Your motherboard documentation will provide you with the information you need.

What do I need to know about M.2 connectors?

On the host, connectors are called sockets and have unique mechanical keys. This means that modules cannot be used interchangeably between sockets. There are three sockets: one for Wi-Fi, Bluetooth, NFC, or Wi-Gig, one for WWAN or SSD, and one SSD drive socket for SATA or PCIe.

Make sure you’re getting the best speed and performance possible from your SSD with help from Delkin. Contact us today to learn more about industrial M.2 SATA connectors.

Login

Login Register

Register