Industrial SLC microSD

With the Industrial Internet of Things (IIoT), applications increased popularity for the industrial market, and the size of the applications shrink the storage requirements become more critical. IIoT requires storage with a small form factor, industrial temperatures, robustness, reliability, and low power. SLC microSD (aka Trans Flash) integrates all these requirements in a small SiP (System in Package).

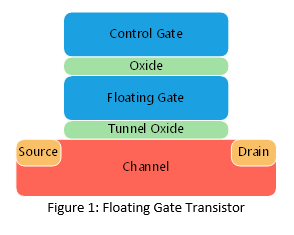

Delkin Industrial SLC microSD (Single Level Cell) solutions are widely adopted in industrial applications. Delkin Industrial SLC microSD is a controlled Bill of Material (BOM) minimizing qualifications cycles, a key factor in reducing TCO (Total Cost of Ownership). microSD SLC uses floating gate technology to hold electrons.

The presence of electrons in the floating gate, depicted in Figure 1, is read as a 0 (programmed) and the absence of electrons in the floating gate is read as a 1 (erased). The floating gate is charged by using Fowler -Nordheim tunneling (FN tunneling) in which electrons are tunneled through the oxide layer by applying a high voltage to the control gate, the electrons store in the floating gate even after the microSD is powered off. Applying a high voltage to the Channel (substrate) will discharge the floating gate and place the cell in an erase state. In the SLC cell, the floating gate state is binary, it is either charged or not, 0 or 1.

Delkin Industrial SLC microSD is built with SLC NAND memory which is ideal for harsh environmental conditions that are experienced by most IIoT applications. Delkin microSD is rated to operate in temperatures from -40C to 85C. The SiP form factor provides robustness, able to withstand environmental conditions susceptible to high shock, vibration, and humidity. The reliable SLC NAND memory is rated for 60,000 P/E cycles, ideal for storing system critical data in industrial applications.

Typical operational power consumption of 396mW @ 3.3V and a standby power consumption of 825 microW makes the Delkin Industrial microSD an ideal memory device for power-sensitive IIoT applications.

The Delkin Industrial microSD robustness described above make it ideal for any applications that require:

- Data to be stored and used by the system

- Reliable system booting information

- Telemetric data storage

Industrial Delkin microSD supports Serial Peripheral Interface (SPI) mode in addition to Full SD Mode. The advantage of SPI channel communication is the support by most microcontrollers and allows for the Delkin Industrial microSD to seamlessly integrate with most industrial applications. Compared to SD mode, where up to 4 bidirectional data signals can be used for data transfers, SPI mode performance is low. SPI protocol consists of four signals: Chip Select signal (CS), Clock (CLK), Data In signal (DI), and the Data Out signal (DO). The command structure is 8bit byte built, byte-aligned to the CS signal, and uses the same SD mode command set.

In addition to the SPI mode, the Delkin microSD cards feature SMART information capability:

- Run-Time bad blocks – Blocks that have worn out or compromised during operation

- Remaining Spare blocks – Blocks used by the Micro SD card to replace the Run-Time Bad Blocks

- Erase count data – The amount of P/E cycles endured by the NAND

- Power cycle count – The number of power cycles experienced by the microSD card

The SMART data allows the user to monitor the life of the Industrial microSD card. The SMART data can be read from the Industrial microSD card locally (i.e. at a service center, laboratory) by removing the card from the application, plugging it into a Delkin SD card Reader, and launching the Delkin Dashboard Software. The SMART data allows for remotely card health monitoring with Delkin provided libraries for inline host integration. The SMART data can be used to extrapolate the life cycle of the microSD card as well as monitor host behavior relative to the microSD card.

At Delkin, our team is available to answer your questions today, so contact us for more information.

ORDER DELKIN INDUSTRIAL FLASH STORAGE TODAY through our distribution partner Newark.

Login

Login Register

Register