Answering Questions about SLC CompactFlash

SLC Compact Flash—known more commonly as CompactFlash or CF—is one of the most reliable and most popular forms of storage on the market. In SLC format, CF memory cards are capable of supporting host devices in industrial environments without any kind of loss of function. For engineers and designers looking for a failsafe storage solution for devices in high-stress environments dealing with mission-critical data, it’s hard to find a better solution than CF memory cards. If you’re considering SLC CompactFlash for your application, check out the following answers to some common questions that many designers and OEMs have.

What are the benefits of SLC CompactFlash?

SLC CF cards come with two advantages. The first is being designed using the CompactFlash Association guidelines. CF is a form factor that has been around since 1994, and unlike some other storage formats, it has been used in industrial products since early in its product life. CF technology itself has continued to evolve since that time, with continuing improvements in performance and the addition of features like SMART, or Self-Monitoring, Analysis and Reporting Technology—all within the same well-known format that is governed by the CompactFlash Association.

The second advantage is the SLC technology. SLC is short for single-level cell, and it is a form of NAND flash memory in which only one bit of data is stored on each cell. As a result, there are fewer risks of data loss during power fluctuations. Because only one bit needs to be written and read per cell, processing times are much faster compared to other kinds of flash memory. For industrial grade devices, this combination of high speeds and data protection is the draw of SLC CF cards.

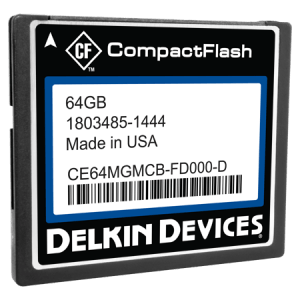

What SLC CompactFlash card capacities are available?

The wide range of capacities is one of the attractions for many SLC CF card users. Depending on the card you choose, you can get storage ranging from 128MB to 64GB, all with SLC formatting. As industrial grade memory cards, these SLC CF cards also feature extended temperature, vibration, and shock tolerance and have integrated SMART features to allow easy monitoring of the memory within the host device. This helps to reduce the risk of failures in the field.

What happens when there are parts changes on SLC CF cards?

Delkin’s SLC CF cards feature a controlled BOM. This means that no changes will be made to critical flash components, including the controller and firmware, without a product number change. Customers also get advanced notice of these changes, so they can plan accordingly to avoid device outages during the transition.

Find out more about Delkin SLC CompactFlash memory cards by contacting one of our product representatives. We’re happy to answer your questions about features, customization, and host-specific testing.

Login

Login Register

Register